Understanding Diecasting: The Process and Its Purposes

Understanding Diecasting: The Process and Its Purposes

Blog Article

Diecasting is a specialized production process that transforms the hot metal into precisely-defined elements using high-pressure molds. This method has been deemed indispensable for a wide range of industries such as automotive, aerospace, electronics as well as consumer products, due to its capacity to make complex shapes with remarkable reliability and accuracy. In combining the principles of metallic engineering with cutting-edge technology Diecasting provides unrivaled precision and efficiency, making it a cornerstone of modern manufacturing. This article explores the intricate realm of diecasting looking at its procedure, advantages in a variety of ways.

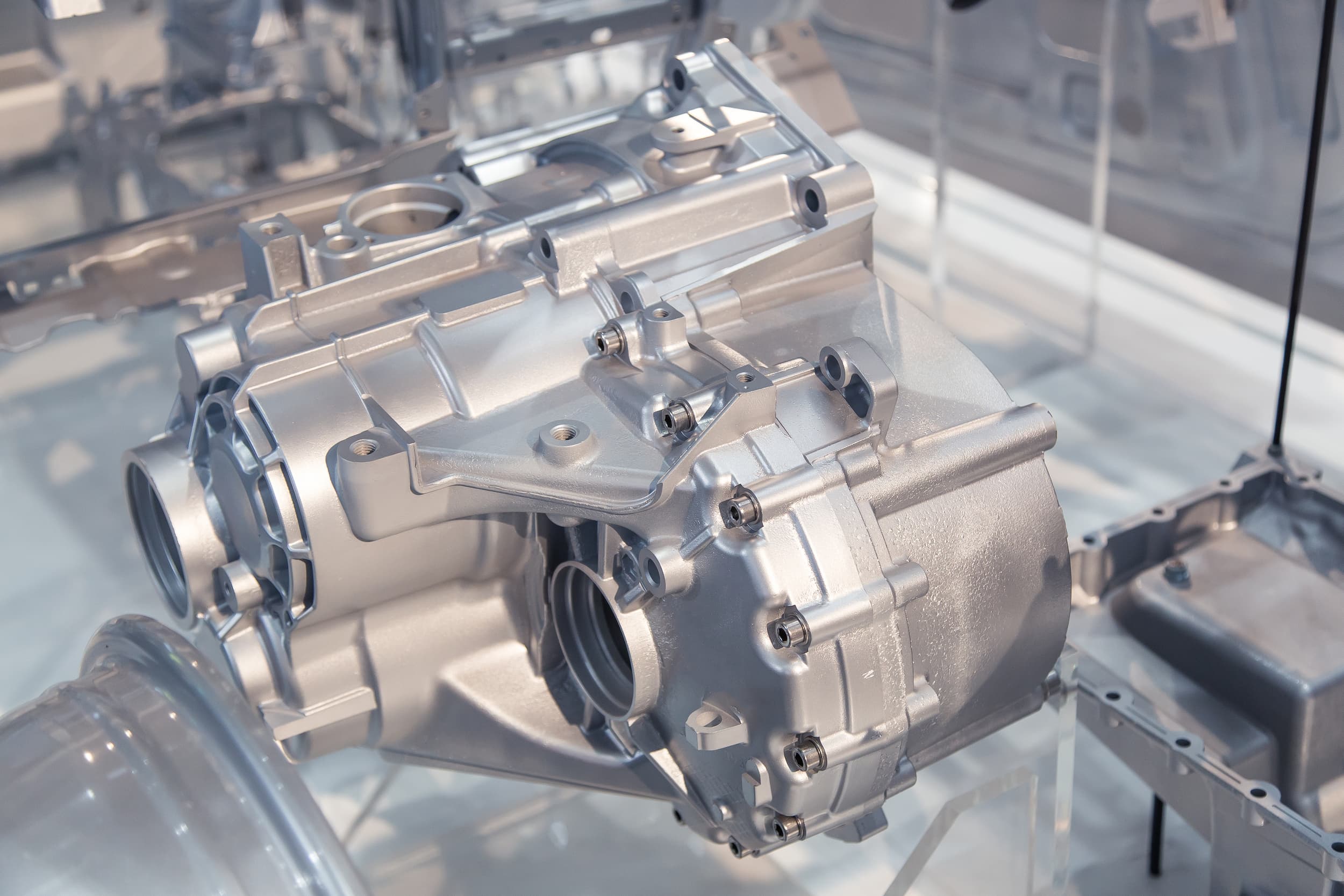

The diecasting process begins with the creation of molds, also referred to as a"die," which is usually made of the hardened steel. The die is made to stand up to the pressures and temperatures involved when diecasting. When the mold is finished for use, the metal that is molten, typically made up of aluminum, zinc, magnesium, or copper, is heated to a liquid state and then in the mold cavity under pressure that is high. The pressure will remain constant until the metal solidifies, insuring that the solidified metal is able to fill every area of the mold, with intricate details and thin walls. After the metal has cooled and formed, the mold is unveiled, and then the completed piece is released. This technique allows for high precision and consistency for the manufacturing of metal parts.

One of the major advantages of diecasting is its capacity to manufacture parts with high dimensional accuracy and smooth surface finishes. Injections of high pressure guarantee that the molten metal is precisely molded in the mold resulting in parts that require minimal machining or finishing. This accuracy is particularly useful to create complex geometries and thin-walled sections that would be challenging or impossible to achieve by other processes of manufacture. Diecasting also produces parts with tight tolerances and high repeatability, which makes it an ideal method for mass production. Its effectiveness can also result in cost savings because the higher productivity rates cut down on labor and also material waste.

Diecasting also offers considerable benefits when it comes to the mechanical properties and performance. Diecast parts are well-known for their durability and strength as they are the most important characteristics for components used in harsh environments. The formation of fine-grain structures in the process of rapid cooling the metal helps to create these excellent properties, which make diecast products suitable to be used in highly stressed environments. Diecasting also allows the inclusion of thin walls as well as complex features without compromising the integrity of the finished item. This capability is particularly advantageous for aerospace and automotive sectors, where cutting down on weight and retaining structural strength is essential to improve fuel efficiency as well as overall efficiency. To obtain more information kindly head to Senadiecasting

Diecasting's capabilities go beyond the mechanical advantages to its flexibility in a variety of areas. In the realm of electronics, it is employed in the manufacture of enclosures connectors and heat sinks which ensures that equipment is secured and work efficiently. The process is also widely used in producing everyday consumer things, from the kitchen appliance to power tools, where the quality and reliability are crucial. Diecasting is a process that can produce detailed and complicated parts can make diecasting a desirable option to engineers and designers seeking to innovate and improve product performance. In allowing a variety of different metals and the integration of features that are intricate it allows for the development of innovative products in a variety of different industries.

Diecasting is the pinnacle of manufacturing technology, offering a blend of precision, effectiveness, and flexibility which is unparalleled by other manufacturing processes. Its capability to manufacture complex, high-quality components with superior mechanical properties makes it essential in various industries, from automobile to consumer electronic products. The effectiveness and savings in material associated with diecasting underscore its value in high-volume production. Furthermore, its ability to adapt allows it to meet the changing demands of modern manufacturing. While industries push into the realm of creativity as well as performance, diecasting will remain an important tool providing the basis for advancements, and also facilitating the creation of innovative products which shape the world.